Warehousing, storage, large distribution warehouses, big box retailers, and storage facilities are becoming increasingly common with the advent of online shopping, the personal accumulation of personal items that exceed available storage space, and the consolidation of fabrication and assembly buildings. The International Building Code (IBC), NFPA 13, and NFPA 25 all contain special requirements for any combustible storage that exceeds 12 feet in height or, for high hazard storage commodities, for any high hazard storage above 6 feet in height.

The code scoping comes from Section 413 of the IBC, which directs the designer to the IFC. Section 413 reads as follows:

Somewhat confusingly, the code only defines high piled combustible storage in the IFC. The definition is provided within Chapter 2 of the IFC and reads as follows:

High-Piled Combustible Storage Defined:

Thus, the designer is to apply the high-piled provisions of the fire code if the storage meets this definition.

Chapter 32 of the IFC is the section of the code that prescribes the requirements for high-piled combustible storage. The variables that affect the required fire and life safety systems in such an occupancy include, but are not limited to:

- Type of commodity stored (how hazardous the storage material is)

- How the commodity is stored, including, but not limited to:

- On shelves

- On racks

- Stored directly on the floor

- Open or Closed Racks

- The area of the high-piled combustible storage area

- Whether or not the public can access the storage area

- The arrangement of the storage:

- Number of racks (single, double, or multiple)

- When stored directly on the floor, pile domensions, area, and volume

- Aisle space between sections of storage

- The height of the storage

- The presence of any automated storage systems (powered storage systems that move material within racks)

High-Piled Combustible Storage Occupancy Fire and Life Safety Features

Taking all of these factors into account, Chapter 32 of the IFC prescribes the required fire and life safety features that are necessary for a code compliant occupancy. The required fire and life safety features can be comprised of the following:

- The presence of an automatic sprinkler system

- Required automatic fire/smoke detection system

- Enhanced egress around the perimeter of the building that is accessible by firefighters

- Smoke and heat removal via special smoke and heat vents

- Draft curtains

High-Piled Combustible Storage Sprinkler Systems

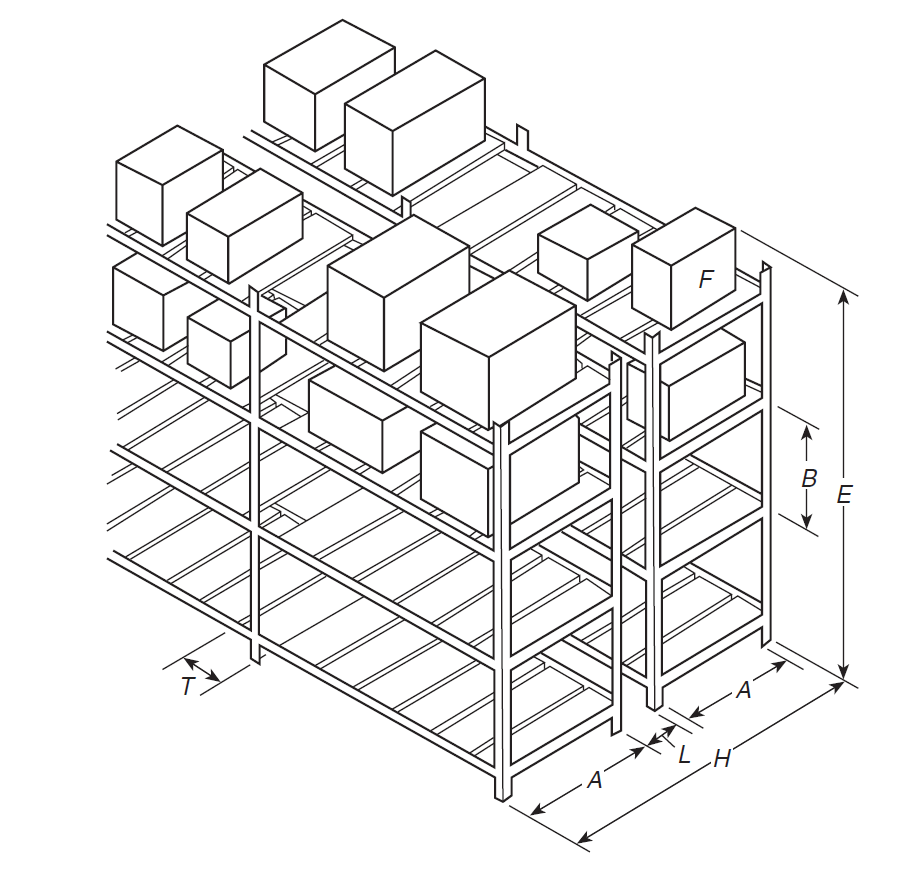

Most high-piled storage occupancies require a fire sprinkler system. What’s more, the fire sprinkler system has to be specially designed in order to ensure it can protect the storage hazard(s) present in the storage building. NFPA 13: Standard for the Installation of Sprinkler Systems has Chapters 12 through 21 dedicated to these special requirements. The variables that affect the sprinkler system design are the same as numbers 1, 2, 5, 6, and 7 above. In addition, the aisle width (i.e., the space between racks or piles or storage) determines the sprinkler criteria.

Figure 1: Double Row Rack Storage with Open Racks

The storage chapters of NFPA 13 that prescribe design criteria are organized into storage arrangement (e.g., rack storage versus solid piled) and whether the protection is for high-hazard storage, such as Group A plastics, or conventional commodities, which are classified as Class I, II, III, and IV.

One of the most confusing aspects of using NFPA 13 to design a storage sprinkler system is that there are three different system types. For simplicity, and the most common applications, “system type” refers to wet type sprinkler systems. Wet type sprinkler systems are those that have pressurized water within all of the piping and water sprays immediately from the sprinkler heads upon sprinkler head activation. These four types of sprinkler systems are as follows:

- Control Mode Density Area Sprinkler System (CMDA)

- This is the type of system commonly used in typical sprinkler systems in ordinary buildings. It uses design curves of gpm/ft2 versus system activation area to prescribe the sprinkler system flow rates

- Control Mode Specific Application (CMSA)

- These types of sprinkler systems have been specifically designed and tested to produce large droplets of water that control the spread of fire

- Early Suppression Fast Response (ESFR)

- These types of sprinkler systems have been specifically designed and tested to suppress fires

Each of these system types can be subject to “in-rack” sprinklers. In-rack sprinklers are supplementary sprinklers that are installed on piping that runs directly above storage within racks. Most building owners want to eliminate the requirement of in-rack sprinklers because they limit the ability to reconfigure racks, can accidentally be damaged by material moving systems and cause water damage, and create extra demands on the firewater supply.

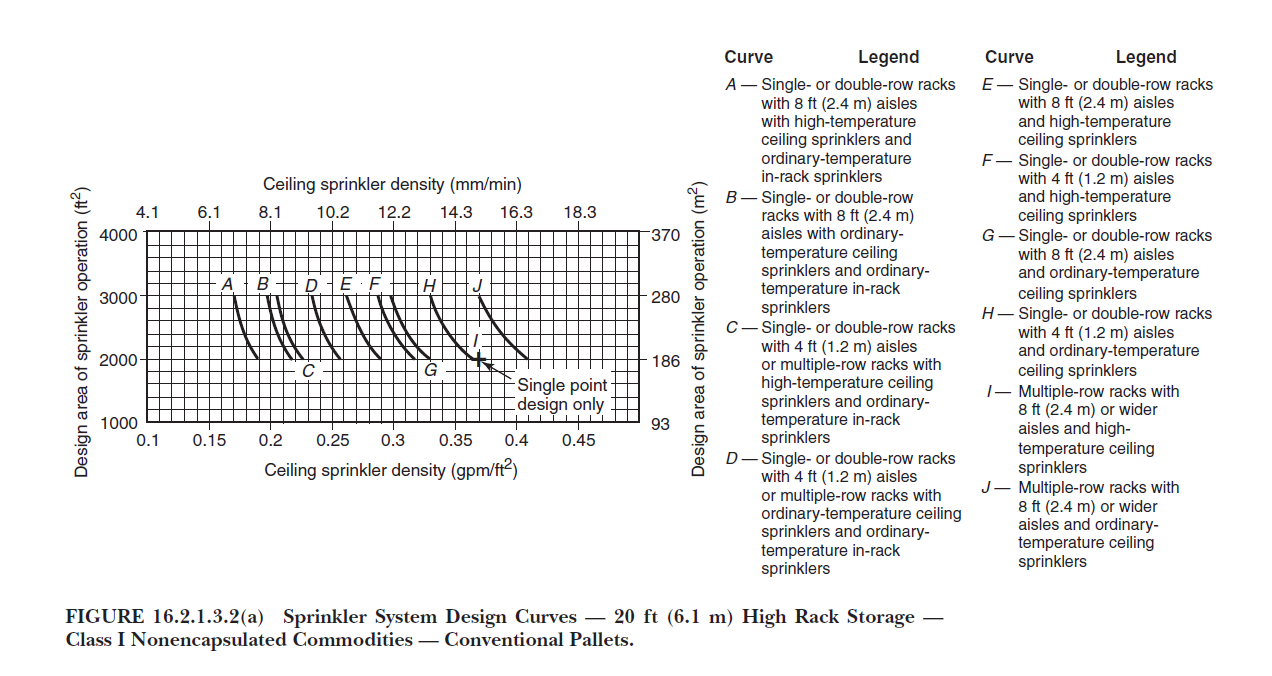

Figure 2 shows the curves that would be used to determine the discharge density of a CMDA system.

Figure 2: Design Density Curve for CMDA System

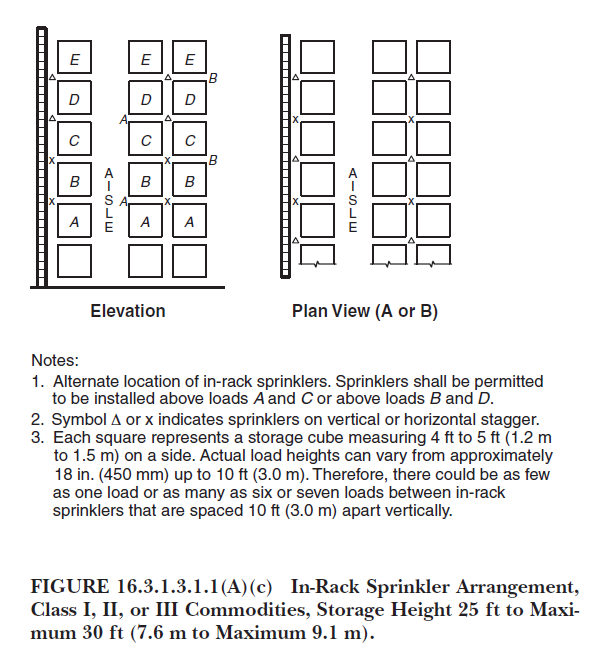

Figure 3 shows the requirements for installing in-rack sprinklers for a particular design.

Figure 3: In-rack Sprinkler Requirements

Out of the three system types, it is the most difficult to obtain that of the CMDA system, and the CMDA system most often requires in-rack sprinkler systems.

Determining the design requirements for CMSA and ESFR systems is much more straightforward. Within NFPA 13, there are tables that list all of the design variables and then prescribes the required sprinkler head and operating pressure at each sprinkler head. It is less likely, with CMSA or ESFR sprinkler systems, to have in-rack sprinkler system requirements.

A designer using an ESFR sprinkler system is obviated from any smoke and heat vent requirements from Chapter 32 of the IFC. Smoke and heat vents are an expensive feature for any storage building, so knowing this exception can often direct owners and designers to ESFR systems.

Change of Use and Occupancy

If an existing warehouse is changing its storage such that it will be classified as high-piled combustible storage occupancy, or if it is reconfiguring, adding, removing, or otherwise changing its storage, the warehouse needs to be reevaluated to all aforementioned codes and requirements. If this is not done, the fire inspector normally requires it, after noticing such changes during required periodic fire inspections. NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems is the standard that requires this reevaluation.

Submittals

Chapter 32 of the IFC requires a detailed submittal for High-Piled Combustible Storage, which results in a special permit. A special report prepared by a fire specialist is required. This report is a road map to the requirements mentioned above. A storage/warehouse plan is also required that shows the architectural and storage features of the facility. Such features include, but are not limited to: arrangement of egress doors, location and size of smoke and heat vents, area of storage, height of storage, commodity type of storage, required versus proposed sprinkler system design criteria, and the presence of a fire detection system. The special report is utilized by a fire sprinkler designer to prepare fire sprinkler shop drawings which are used to obtain a fire permit to install or modify the sprinkler system.

The Detailed Details

This article has attempted to provide an overview of the IBC, IFC, NFPA 13, and NFPA 25 requirements for high-piled combustible storage occupancies. While this has been achieved, it must be noted that each of the requirements glossed over is a step that requires considerable time and expertise. Significant steps that have not been discussed in detail are:

- How to determine the commodity classification of stored material and how that impacts the facility and fire sprinkler system design.

- This is performed by carefully comparing what the stored material is, how it is bundled and packaged, and its type of pallets to the definitions within NFPA 13 and Chapter 32 of the IFC. The packaging can cause an otherwise non-high-hazard commodity to become a high-hazard one.

- The required design of the sprinkler system, which is based not only on hazard variables, but the wants and needs of the owner and the type of sprinkler system to be installed

- A detailed review of the storage chapters of NFPA 13 is required with a deep understanding of the scoping and content of each chapter

- The design of the fire detection system, which will most likely be done by a fire alarm system designer

- If such a system is required, it must be activated automatically by heat or smoke detectors, and the system must be designed per NFPA 72: National Fire Alarm and Signaling Code. If the building doesn’t already have a fire alarm system, this system will be required to be monitored by a third party monitoring company, which will require a subscription service contract by the owner.

- Special Building Egress: a special arrangement of building access doors for the fire department is often required in these facilities. Detailed spacing and door positioning is necessary

- Such egress doors are required every 100 feet of building perimeter length.

- Smoke and Heat Vents: the overall venting area, spacing of the vents, and selection of the vents to be used are part of this step. ESFR sprinkler systems eliminate the need for these vents

- Draft curtains: the type of draft curtains used, their depth, spacing, and other details

- Solid pile dimensions: solid piled storage (directly on the floor) has aisle requirements, pile size limits, and pile height limits.

Conclusion

In order to properly design a high-piled combustible storage warehouse, a specialized team of professionals is required. This team is normally comprised of the following:

- A fire protection engineer, certified fire protection specialist, or NICET IV technician to write the technical report

- A company that specializes in warehouses, material movement, or logistics

- Conventional building design team

- Sprinkler Designer

- Fire Alarm Designer

- A fire protection or mechanical engineer for the smoke and heat vent design

- A fire protection engineer for draft curtain design

The high-piled combustible storage submittal is typically evaluated by the Authority Having Jurisdiction’s fire prevention, fire code, or fire department. Larger departments have licensed fire protection engineers who evaluate the submittal for code compliance.

Owners and building designers are urged to have the proper team in place to ensure the success of their next high-piled combustible storage project.

John P. Stoppi Jr. is a licensed fire protection and mechanical engineer, and a certified building and fire inspector. He has helped designed numerous high-piled combustible storage occupancies and has inspected high-piled occupancies for fire code compliance.