Draftstopping, fireblocking, and firestopping are all terms contractors and designers have heard at one time or another. Almost certainly, these same people, at one time, may have been confused by these terms and have mistaken one for the other. What’s worse, one may have applied fireblocking when firestopping was required or some other mistaken combination. In this article, we will explore exactly what these three terms mean, when these protection measures are required, how to design and install them, and what products or materials are approved to apply them.

Generally speaking, draftstopping and fireblocking are required for certain aspects of combustible construction and often in residential construction (because almost all residential construction is combustible). On the other hand, firestopping may be required across all construction types, and is used mainly to seal penetrations through fire resistance rated construction assemblies, such as piping or HVAC ductwork.

Draftstopping

Like most code provisions, the most prudent thing to do when pondering them is to consult the official definitions before applying them. While there are draftstopping requirements in both the 2018 International Residential Code (IRC) and the 2018 International Building Code (IBC), it is only defined in the latter as:

While this definition states “…movement if air…” what it is really referring to is the products of combustion, such as smoke and hot air, produced during a fire. The idea is to place material of limited or no combustibility to block the movement of these gases in specific locations. Again, the important thing to remember is that draftstopping is only required in commercial combustible construction and in residential construction, the latter of which is almost always combustible construction. Referring back to the 2018 IRC, draftstopping is required in the following locations:

Note that this requirement only applies when there are usable spaces both above and below the floor-ceiling assembly. It would not apply to the first floor assembly with a crawl space below or a second floor assembly with an attic accessible only through a hatch above. It would apply if a basement, finished or unfinished were below, or if an attic accessible through a permanent stair were above. There are essentially two scenarios, when the above apply–where draftstopping would be required:

- The floor-ceiling joists do not meet the minimum material requirements considered to be draftstopping and the concealed area exceeds 1,000 square feet;

- There is a suspended or drop ceiling that is hung below the joists and there is open air space above the suspended or drop ceiling.

For the first scenario, Section 302.12.1 of the IRC must be consulted for what materials constitute approved draftstopping:

Picture a floor-ceiling system built from Trus Joists (TJIs) with usable floor space above or below. If you have never encountered this floor-ceiling system, they are built from engineered wood with a thin web (the middle of the joist) and thicker flanges at the ends. They appear as Figure 1 below:

Figure 1: TJI Joists

For discussion purposes, let’s presume that the webs are 1/4″ and do not qualify as draftstopping materials per Section R302.12.1. Let’s also assume that they form the floor-ceiling of a room that is 40 feet by 40 feet, or 1,600 square feet. A 1/2” thick piece of drywall would have to be installed across the entire span or spans of one of the members to provide draftstopping protection. Per Section R302.12, this segment of drywall should be installed in the middle of the span, which would be 20 feet from the walls.

For the second scenario, an interstitial space of a suspended ceiling would also have to be segmented into two or more sections using the approved materials. Again, picture a 20 foot by 20 foot space with usable space above or below that utilizes a suspended ceiling with an open interstitial space. A vertical segment of 1/2” drywall would have to be installed near the middle of the space to separate the interstitial space into two equal areas of 800 square feet each. In this construction scheme, depending on the construction of the drop ceiling, it may be difficult to mount such a piece of drywall, because the membrane of the suspended ceiling may be acoustical ceiling tile (ACT), which is nonstructural and can only support a limited amount of weight.

Fireblocking

Unlike drafstopping, fireblocking is meant to prevent the passage of fire in open spaces or voids of floor or wall construction. Within the 2018 IBC, it is defined as:

There are more instances in the 2018 IBC where fireblocking is required than within the 2018 IRC. Generally, it is required where concealed space construction creates small, open spaces within it, or where electrical cabling or piping penetrate wood wall studs. Also, it is needed between floor to floor transitions. Balloon construction renovations often include the retrofitting of fireblocking because such construction naturally has small spaces between the flooring and the wall framing. Besides these instances, it is often used for:

- Stairways

- Chimneys and Fireplaces

- Exterior wall coverings

- Annular spaces around penetrations of floors and ceilings

The materials permitted for fireblocking are listed in Section B718.2.1:

Within wall construction, fireblocking is most often needed when wood studs are erected in front of a masonry wall, where staggered studs are used, and where walls are furred out. In platform framing construction, the construction naturally seals any voids or spaces and specific fireblocking provisions need not be contemplated. As stated earlier, wiring and piping penetrations through wood studs need to have the annular spaces protected by fireblocking. The most often material used for this is a product commonly referred to as “fire foam.” Fire foam is applied via an aerosol like container and appears similar to sprayed insulation. Fire foam is also used to seal wall voids and other annular spaces, but its maximum thickness is limited. Unfortunately, this product is often mistaken for firestopping, and is often erroneously used as such. Fire foam is normally colored orange, and firestopping is normally red. Fire foam has to meet the requirements of ASTM E84 (modified) or a similar standard. A container of fire foam is shown in Figure 2 below.

Within wall construction, fireblocking is most often needed when wood studs are erected in front of a masonry wall, where staggered studs are used, and where walls are furred out. In platform framing construction, the construction naturally seals any voids or spaces and specific fireblocking provisions need not be contemplated. As stated earlier, wiring and piping penetrations through wood studs need to have the annular spaces protected by fireblocking. The most often material used for this is a product commonly referred to as “fire foam.” Fire foam is applied via an aerosol like container and appears similar to sprayed insulation. Fire foam is also used to seal wall voids and other annular spaces, but its maximum thickness is limited. Unfortunately, this product is often mistaken for firestopping, and is often erroneously used as such. Fire foam is normally colored orange, and firestopping is normally red. Fire foam has to meet the requirements of ASTM E84 (modified) or a similar standard. A container of fire foam is shown in Figure 2 below.

Figure 2: Fire Foam for Fireblocking (not firestopping)

Since it is important to differentiate between fire foam and firestopping, an application of fire foam is shown below in Figure 3:

Figure 3: Fire Foam Field Application

Firestopping

Firestopping is the most robust form of protecting penetrations through basically any type of fire resistant construction in buildings of any construction type. For a review of all of the types of fire resistant construction, please see the article here. If you are unfamiliar with construction type classifications, please see an overview here. In addition, firestopping is required at joints between floors and walls where fire resistant construction is installed.

Firestopping must be approved to specific standards, namely ASTM E814 or UL 1479. If you ever want to definitively differentiate between fireblocking and firestopping, look for these approvals on the firestopping product. FIreblocking is not required to be approved to these standards. Firestopping is normally colored red, but can also come in clear, yellow, or other colors. So color alone is not enough to identify firestopping. Colloquially, firestopping is referred to as “fire caulking,” and many contractors refer to it by this name in the field. A tube of firestopping being applied can be seen in Figure 4 below.

Figure 4: Firestopping Application

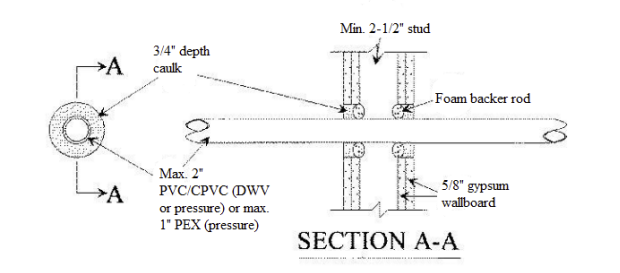

Firestopping normally has to be applied in a specific manner based on the construction being penetrated, what is penetrating it, and the size of the penetration. There are limits to the thickness of the firestopping. How deeply it must be embedded into the material is also a requirement. Additionally, sometimes sleeves or other coverings are needed over the penetrating material. Design sheets are provided that show these details, and they must be strictly followed in their application for approval and effectiveness. An example of such a detail is shown in Figure 5.

Figure 5: Typical Firestopping Detail

Note that in this example, there are the following limitations for the use of the detail: the piping diameter cannot exceed 2”; the firestopping depth is 3/4″; the piping may be waste or supply piping; the studs must be a minimum of 2.5” thick; and a foam backer is required. Firestopping details are often found in the system design documents or they are procured by the installer. Firestopping is installed by the system contractor, such as an electrician, plumber, or sprinkler contractor. On specialty projects, such as in hospitals, individual contractors install through their penetrations and the firestopping contractor firestops them after they are installed. The quality and accuracy of firestopping is normally higher when a firestopping contractor is responsible for its installation. Figure 6 shows an example of a construction joint being firestopped.

Figure 6: Firestopping Joint

These horizontal applications of firestopping also have special requirements that depend on the rating of the members being sealed, the materials being protected, and the construction of the members that are forming the joint (fire rating, fire resistant barrier type, etc.). For example, a fire wall would have different requirements than a fire partition.

For high risk buildings, the 2018 IBC requires Special Inspections for firestopping. That is, an approved Special Inspection Agency must inspect the firestopping application in accordance with ASTM E2174. Such agencies and inspectors are third party contractors hired by the owner and supplement the inspections of the local Authority Having Jurisdictions. For more information regarding special inspections, consult Chapter 17 of the 2018 IBC.

Conclusion

In increasing degree of protection, draftstopping, fireblocking, and firestopping are all methods used to guard the passage of smoke and fire through voids, penetrations, and joints in construction. Draftstopping is used to guard the passage of smoke in concealed spaces when combustible construction is used. Fireblocking protects the passage of flame in concealed spaces and voids in combustible construction. Firestopping protects penetrations and joints in all types of construction. Various materials are allowable for draftstopping and fireblocking while firestopping has to be approved to specific standards. Fire foam used for fireblocking is often confused with firestopping. The best method of confirming that firestopping materials are permitted is to ensure it is approved to the standards, which must be listed on the container itself or in its product datasheet.

John P. Stoppi Jr., PE, FPE, MCP, CFI is experienced in the design and inspection of these protection methods. He has inspected residential and commercial draftstopping and fireblocking as well as large commercial firestopping projects in high rises and hospitals. For questions about these requirements, please feel free to contact him.